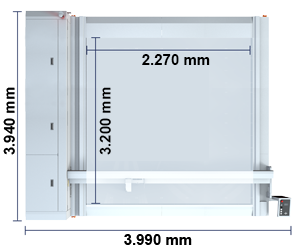

Technical specifications of the CO₂ laser machine XL-3200:

Working area (w x l): | 2,270 mm x 3,200 mm (89.3" x 125,9") |

Which options do we offer you?

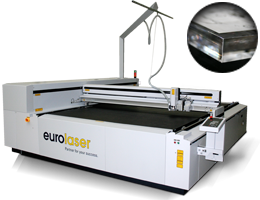

Textile machining with laser systems by eurolaser

We can customize the technology exactly to the needs of your application through the modular design of our laser systems. You will receive from us a laser machine specially configured for your requirements and designed to meet your needs which will arise in later use.

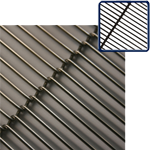

A special table concept is used for textile machining. This comprises a stainless steel wire mesh and is particularly suitable for thin and flexible materials. On the one hand, this is used as the material support for the machining process and, on the other, the transport element for the Conveyor System.

To put together the ideal laser system for your needs, we test your material in advance and then recommend the laser power, machining area and optional automation systems. You benefit from our expertise, acquired from over 10,000 successful application samples.

Automated processes for your laser machine

Higher productivity, more economical working - save time and money

Conveyor System

By using this automatic material feed, textiles can be fed for laser cutting directly from the roll and routed after laser cutting directly to a table extension. With a high degree of connecting accuracy after a material feed cycle, sections, which for all practical purposes are endless, can be produced.

The bale material is fed via an automatic feeding unit. An feeding system edge controller ensures accurate positioning of the material. There is even an option to add a winding unit to the Conveyor System. This is used for the even winding of previously processed textiles and this accordingly results in a completely automated cutting process.

Optional extras

Customized options simplify everyday tasks and increase your possibilities

POSITIONplus - Optical Recognition System

Automatic camera detection enables printed materials to be cut out precisely along the printed outline. Even copying tolerances in the printed format can be compensated by software control.

Label Module

Label your individual pieces quickly and in a single operation for further processing. Or mark your products with your brand logo.

Ink Printer Module

Label your work pieces or stick-on labels directly with the precise Ink Printer Module. The high resolution makes it possible to print fine writing and graphics.

Exhaust and filter units

Suction devices are selected to match your application and the table concept of your laser system. This guarantees complete emission extraction above and below the material.

Cooling units

The high-quality energy efficient cooling units are fitted with electronic temperature controllers and monitoring systems, so that they always control ideal conditions for laser beam sources, in order to guarantee constant performance.

Please call for your individual consulting!