What are the benefits of cutting polyurethane with laser?

- Clean and perfect cut edges - no reworking necessary

- No material fixation necessary – thanks to the vacuum table

- No cleaning of the knives necessary - no parts stick after cutting

- No tool wear so therefore consistently high cutting quality

- High degree of flexibility in the choice of contours – without any need for tool construction or changeover

What additional benefits do eurolaser CO₂ laser cutters offer?

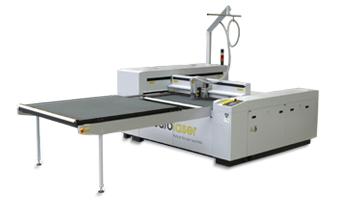

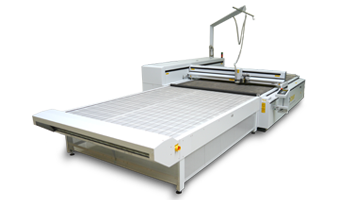

- High level of flexibility due to the combined cutting with knife tools and CO2 lasers on a one cutter

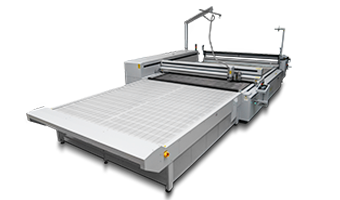

- Unique choice of different table sizes – suitable for all standard sizes

- Efficient automation functions for optimum utilization of the laser system

- Special tables for ideal positioning of the material during laser cutting

- Optical camera recognition for the laser cutting of printed polyurethane

- Conveyor system for fully-automatic laser processing of textiles directly from the roll

- Processing of very large formats thanks to seamless continuation of cutting

- Large-format engravings over the entire working area

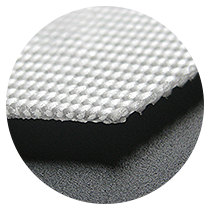

Material information for the laser cutting of polyurethane:

Polyurethane (PUR) is a plastic or synthetic resin. Its properties make polyurethane a versatile material that is very durable, mould and mildew resistant and, depending on manufacture, hard and brittle or soft and flexible. The properties of PUR determine how it is used. For example, rigid foam is used in the shoe industry for the soles of shoes, for sponges for domestic use and for insulation purposes. Soft foam made of polyurethane is used, for example, for inlays in the packaging industry. Polyurethane is also used for foilsand textiles, in particular for technical applications. Even for larger quantities laser cutting now constitutes a real alternative to conventional processing methods such as die and knife cutters (cutting plotters). More and more companies have come to recognize the benefits of high precision and virtually maintenance-free processing that the tool "laser" has to offer.

Application examples for the cutting of polyurethane with eurolaser CO₂ laser systems:

Names often used for polyurethane:

PUR, PU, Cellasto ®, Elastocoat ®, Elastoflex ®, Elastofoam ®, Elastolit ®, Elastopal ®, Elastopan ®, Elastopor ®, Lupranol ®, Baydur ®, Bayfill ®, Bayflex ®, Baylit ®, Baymer ®, Baytherm ®, Desmodur ®

You will find videos showing the laser cutting of polyurethane at eurolaser.tv

You will find videos showing the laser cutting of polyurethane at eurolaser.tv

We would be glad to advise you on the topic of the laser cutting of polyurethane, on our laser systems and special options for the processing of plastic.