As the managing director of Orgelbau Raffin GmbH in 2008 I was looking for a second mainstay for my company. Laser technology first caught my attention during a visit to the plastics fair Fakuma in Friedrichshafen. I made my way home full of enthusiasm after my first contacts with various laser machine manufacturers. I spent the following few weeks comparing the different offers. Although eurolaser’s offer was not the cheapest, it was their quality and flexibility that won me over. And in my opinion eurolaser was also the most likeable of all the providers.

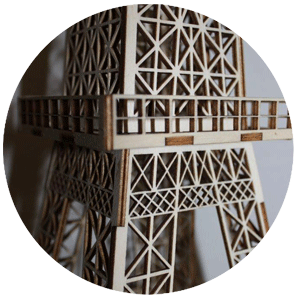

In the very same year, about two months after the plastics fair, I flew with my son to Hamburg to take a closer look at eurolaser. We received a friendly welcome from a member of staff at the airport, who took us to the company's plant. We were given a demonstration of the laser systems and software in the Application Center. The multitude of different application examples convinced us of the flexibility and precision of the technology. We flew back that evening full of positive impressions and enthusiasm for the competence and friendliness of everyone we had met.

About a year later I received an order for cutting wallpaper material (with a PVC content) from a neighboring country. This is where the flexibility of the eurolaser technology came into its own, because PVC is not suitable for laser cutting. eurolaser provided me with a cutter head for testing purposes, which could be installed in my laser system. After the tests proved successful, I purchased my own cutter head with which I was able to manufacture the series for my customer.

As time passed I received more and more orders. I then left the GmbH and in 2012 moved into a production hall in Owingen. Even moving the laser system presented no problem thanks to the support of eurolaser and well trained technicians. The laser system was dismantled on the first day, loaded onto a truck and transported 6 km to the new site. It was then unloaded and placed in the new hall. The system was already up and running by the second day, so I was quickly able to continue producing in our accustomed high quality.

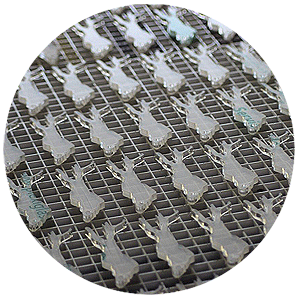

“Today my wife Gudrun and I work as job order manufacturers for the car industry, advertising engineers, lamp producers, the aircraft industry, the satellite technology branch as well as for private persons.”

WK-Dienstleistungen

Owingen / Germany

www.bodenseelaser.de