G. Beneke success story at a glance

High efficiency and enlarged portfolio

- G. Beneke has now been working successfully with eurolaser for more than 10 years and is convinced of the performance of the machine and the service at eurolaser.

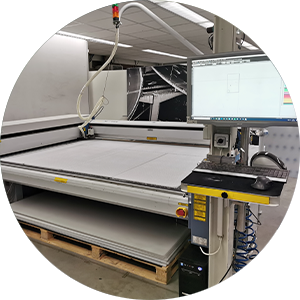

- The new eurolaser system of the 3G series has achieved a noticeable increase in efficiency, as it is possible to cut at higher speeds. The result: More output!

- The new cutter further increases the application possibilities of G. Beneke GmbH. Products can be manufactured that would not have been possible without the laser.

- With the new XL-1600 system, cutting thicker materials at higher speeds is possible.

Challenge G. Beneke: Expand product portfolio with new system

The eurolaser system ran at Beneke for more than a decade and was firmly established in production. In the meantime, developments in machine technology and materials have advanced further and hold new possibilities for users. For G. Beneke, a solution had to be found that would fit equally well into production, while offering higher laser output and providing new possibilities in terms of modularity and expandability. The goal was clear: to increase the company’s production portfolio and optimize process times.

No alternative to eurolaser

“We have been working with eurolaser for over ten years and are very satisfied. The well thought-out, robust systems and the good service are convincing right down the line. When cutting adhesive film and stencils or processing Plexiglas, there is no alternative for us. Without our XL-1600, we would not be competitive. And the new system fits in perfectly here and makes our production even more efficient thanks to the increase in performance!”,

says Gerhard Beneke, Managing Director of G. Beneke GmbH.

Product samples:

G. Beneke GmbH

Wedemark/Germany

www.beneke-beschriftet.com